In the rapidly changing world of industrial operations, the significance of Operational Technology (OT) cybersecurity has surged to the forefront of manufacturing priorities, marking a dramatic shift from its once-marginal role to a central pillar of strategic planning. As manufacturers increasingly integrate cutting-edge technologies such as artificial intelligence and the Internet of Things into their processes, the necessity to safeguard OT environments has become paramount, not just for protection but for enabling innovation and maintaining a competitive edge. This transformation is driven by a growing recognition that cyber threats can disrupt production, erode customer trust, and incur significant financial losses if not addressed proactively. Drawing on insights from Rockwell Automation’s latest findings, this exploration delves into how OT cybersecurity is redefining manufacturing strategies, influencing everything from investment decisions to workforce development, and setting the stage for a more resilient and innovative future in the industry.

The Evolving Role of Cybersecurity in Industry

The perception of OT cybersecurity within the manufacturing sector has undergone a profound evolution, transitioning from a mere compliance obligation to a critical driver of operational success. No longer seen as an afterthought, it is now recognized as essential for ensuring efficiency and gaining a competitive advantage in a digitally connected world. According to recent industry reports, an overwhelming 96% of manufacturers are either actively using or planning to deploy OT security platforms within the next five years, with a significant portion already reaping benefits like minimized downtime and streamlined audits. This shift underscores a broader understanding that robust cybersecurity is not just about averting risks but about creating a stable foundation for adopting advanced technologies that drive productivity and innovation.

This strategic pivot also reflects the urgent need to protect increasingly interconnected systems that are vital to modern manufacturing. As production environments become more digitized, vulnerabilities expand, making cybersecurity a linchpin for business continuity. The focus has shifted from questioning the necessity of such measures to optimizing their implementation for maximum impact. Manufacturers are now prioritizing rapid deployment and measurable outcomes, ensuring that security initiatives align with operational goals. This holistic approach signifies a maturation of the industry’s mindset, where safeguarding OT assets is seen as an investment in long-term stability rather than a burdensome cost, paving the way for seamless integration of emerging tools and systems.

Aligning Security Investments with Broader Objectives

A notable trend in the manufacturing landscape is the alignment of OT cybersecurity investments with overarching business objectives, marking a departure from treating security as a standalone expense. Recent data indicates that 53% of manufacturers now rank the protection of OT assets as a top priority for technology spending, directly linking it to digital transformation efforts such as predictive maintenance and real-time energy optimization. This integration ensures that security measures contribute to operational excellence, with key performance indicators like overall equipment effectiveness (OEE) serving as benchmarks for success. Regulatory frameworks, including Europe’s NIS2 directive and guidelines from the U.S. Cybersecurity and Infrastructure Security Agency (CISA), further amplify the need for this synergy, elevating cybersecurity discussions to the executive level.

Beyond compliance, this alignment fosters a more cohesive strategy where cybersecurity underpins every facet of digital advancement. By tying security budgets to tangible business outcomes, manufacturers can justify expenditures through reduced operational disruptions and enhanced efficiency. This approach also facilitates better resource allocation, ensuring that funds are directed toward solutions that offer both protective and progressive value. As a result, cybersecurity becomes a catalyst for growth, enabling companies to confidently pursue innovations without the looming threat of cyber incidents derailing progress. This strategic integration highlights how security is no longer a siloed function but a foundational element that supports the broader vision of a connected, efficient manufacturing ecosystem.

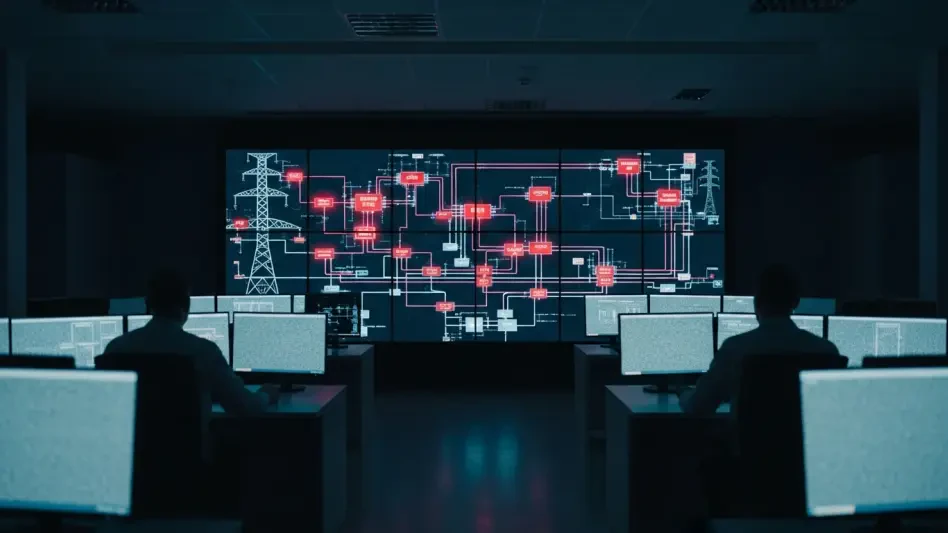

Executive Leadership and Risk Quantification

At the highest levels of corporate governance, OT cybersecurity has captured the attention of executives, with cyber risks now ranking among the top external threats for 30% of manufacturers. This heightened focus at the board level has led to increased scrutiny, where leaders demand precise financial metrics to understand potential losses and assess the maturity of security controls. Security teams are tasked with translating complex technical risks into clear business impacts, ensuring that decision-makers grasp the stakes involved. This trend emphasizes the growing necessity to frame cybersecurity as a critical business issue, directly influencing budget approvals and strategic planning to safeguard organizational interests.

Collaboration with external stakeholders, such as insurers, further underscores the importance of quantifying cyber risks in monetary terms. By presenting data-driven insights on potential financial repercussions, manufacturers can build stronger cases for investment in robust security measures. This executive oversight ensures that cybersecurity initiatives are not only reactive but also proactive, anticipating threats before they materialize into costly disruptions. The involvement of top leadership also fosters a culture of accountability, where every level of the organization recognizes the shared responsibility of maintaining a secure OT environment. This shift in perspective is reshaping how manufacturers approach risk management, making it a cornerstone of corporate strategy rather than a peripheral concern.

Advancements in Secure Technology Solutions

On the technological front, innovations in OT cybersecurity are playing a pivotal role in fortifying manufacturing environments against evolving threats. A significant 31% of manufacturers are now adopting secure-by-design hardware, which incorporates built-in security features like controller-level access controls and signed firmware to address vulnerabilities at the device level. These advancements offer a proactive defense mechanism, reducing risks before they can be exploited in increasingly connected systems. Such hardware solutions complement the broader adoption of security platforms, creating a multi-layered approach that enhances overall resilience.

The integration of these cutting-edge technologies also facilitates safer deployment of interconnected systems essential for modern manufacturing. By embedding security directly into equipment design, manufacturers can mitigate threats without compromising operational efficiency or innovation. This focus on inherent protection at the source represents a forward-thinking strategy, ensuring that new tools and machinery are equipped to withstand cyber challenges from the outset. As a result, companies can pursue digital transformation with greater confidence, knowing that their foundational infrastructure is built to resist intrusions. This technological evolution is redefining how equipment is conceptualized and implemented, prioritizing security as a core component of industrial progress.

Developing a Skilled and Cyber-Aware Workforce

The human factor remains a critical component in the transformation of OT cybersecurity, with 81% of manufacturers emphasizing the need for cyber skills in recruitment and training programs. Building a workforce proficient in secure practices is becoming as fundamental as adhering to safety protocols, ensuring that employees across all levels contribute to a fortified OT landscape. Through certifications, ongoing education, and performance incentives, companies are addressing the expertise gap that often leaves systems vulnerable to human error. This initiative is essential for maintaining a robust defense against threats that exploit lapses in knowledge or procedure.

Beyond technical training, fostering a cyber-aware culture involves embedding security consciousness into everyday operations. Employees are encouraged to view cybersecurity as a shared responsibility, much like workplace safety, which helps minimize risks stemming from negligence or oversight. This comprehensive approach ensures that technological investments are not undermined by preventable mistakes, creating a seamless integration of human and digital defenses. As manufacturers continue to prioritize workforce development, the industry moves closer to a future where cyber literacy is a baseline expectation, strengthening overall resilience against an ever-evolving threat landscape.

Addressing Cultural Challenges in Security Adoption

Despite technological and strategic advancements, cultural barriers continue to pose significant challenges to the widespread adoption of OT cybersecurity in manufacturing. Approximately 25% of manufacturers report employee resistance to new security protocols, while an equal percentage points to limited awareness among leadership as a hindrance. These obstacles highlight the need to integrate cybersecurity into the existing safety culture, making it a natural extension of established practices. Initiatives such as recognition programs and cross-functional drills are proving effective in bridging these gaps, encouraging a mindset shift where security is seen as everyone’s duty.

Tackling these cultural hurdles requires a concerted effort to align security objectives with the values and routines already ingrained in the workforce. By framing cybersecurity as a parallel to safety—a non-negotiable priority—manufacturers can reduce pushback and foster acceptance at all organizational levels. Leadership plays a crucial role in this process, setting the tone through active engagement and clear communication about the importance of these measures. Overcoming these cultural impediments ensures that the benefits of advanced security technologies and strategies are fully realized, preventing human factors from becoming the weak link in an otherwise robust system.

Future Steps for Sustained Resilience

Looking back, the journey of OT cybersecurity in manufacturing reveals a remarkable transformation, as it moved from a peripheral issue to a central strategic focus over recent years. The strides made in aligning security with business goals, coupled with executive commitment, showcase how the industry has adapted to escalating cyber threats. Technological innovations and workforce training initiatives demonstrate a proactive stance, while efforts to overcome cultural barriers lay the groundwork for lasting change. Reflecting on these developments, it’s clear that the sector has responded with agility, prioritizing resilience as a key competitive factor.

For the path ahead, manufacturers must continue to build on these foundations by investing in scalable security platforms that adapt to emerging risks. Strengthening partnerships with regulators and insurers can further refine risk assessment models, ensuring that strategies remain relevant. Additionally, fostering a continuous learning environment will keep the workforce equipped to handle new challenges. By maintaining this momentum, the industry can solidify cybersecurity as an enabler of innovation, ensuring that past efforts translate into a secure and prosperous future.