In an era where supply chains stretch across continents and involve countless stakeholders, trust has become a cornerstone of operational success in the U.S. manufacturing sector. Imagine a critical component in a medical device failing due to an undetected counterfeit part slipping through the cracks—such a breach could cost lives and billions in damages. With supply chains growing ever more complex and globalized, the risks of fraud, compliance failures, and cybersecurity threats loom larger than ever. This scenario underscores the urgent need for transparency and integrity in tracking products from origin to end user. The National Institute of Standards and Technology (NIST), through its National Cybersecurity Center of Excellence (NCCoE), has stepped into this critical space with innovative solutions to bolster supply chain trust.

The importance of reliable traceability cannot be overstated as manufacturers grapple with fragmented practices and visibility gaps. These challenges hinder the ability to verify product provenance and ensure adherence to stringent regulations. NIST’s efforts, particularly through its Internal Report 8536 on Supply Chain Traceability, aim to address these pressing issues by providing a structured approach to data management. This report delves into how NIST’s Meta-Framework offers a pathway to enhance trust and resilience across distributed supply networks.

Understanding the Meta-Framework for Traceability

Core Components and Objectives

At the heart of NIST’s initiative lies the Meta-Framework, a strategic tool designed to achieve end-to-end traceability in supply chains. This framework focuses on capturing supply chain events as traceable records, enabling stakeholders to track products and components throughout their lifecycle. Key elements include trusted data repositories for secure storage, traceability records for event documentation, and cryptographic validation techniques to ensure data integrity. These components work together to create verifiable chains of information that span multiple organizations.

The primary objectives of this framework are to verify product origin, ensure compliance with legal and industry standards, and strengthen supply chain resilience. By linking records across ecosystems, it becomes possible to address risks such as recalls or defects with precision. This structured approach not only enhances accountability but also builds confidence among manufacturers, suppliers, and consumers in the authenticity of goods.

Beyond risk mitigation, the framework aims to close visibility gaps that plague multi-tiered supply networks. Its design supports the secure exchange of data while maintaining consistency through standardized models. This adaptability ensures that diverse industries can implement solutions tailored to their specific needs without sacrificing interoperability.

Industry Trends and Stakeholder Collaboration

Supply chain management is undergoing a profound transformation driven by digitization and globalization. As manufacturing networks expand, the reliance on digital systems for tracking and data sharing has surged, amplifying the need for secure and standardized practices. These trends highlight the vulnerabilities introduced by fragmented traceability systems, which often fail to provide a cohesive view of product journeys.

Recognizing these challenges, NIST has fostered a collaborative development process for the Meta-Framework, engaging industry leaders, academic experts, and standards organizations. This partnership reflects a shared understanding that a unified approach is essential to combat risks like counterfeiting and cybersecurity breaches. The consensus points toward the necessity of interoperable solutions that can integrate seamlessly across varied platforms and ecosystems.

Stakeholder input has been pivotal in shaping a framework that balances transparency with the protection of sensitive data. This cooperative effort underscores a collective commitment to advancing supply chain integrity. As digital tools continue to evolve, such collaboration will remain vital to address emerging threats and maintain trust across global networks.

Challenges in Supply Chain Traceability

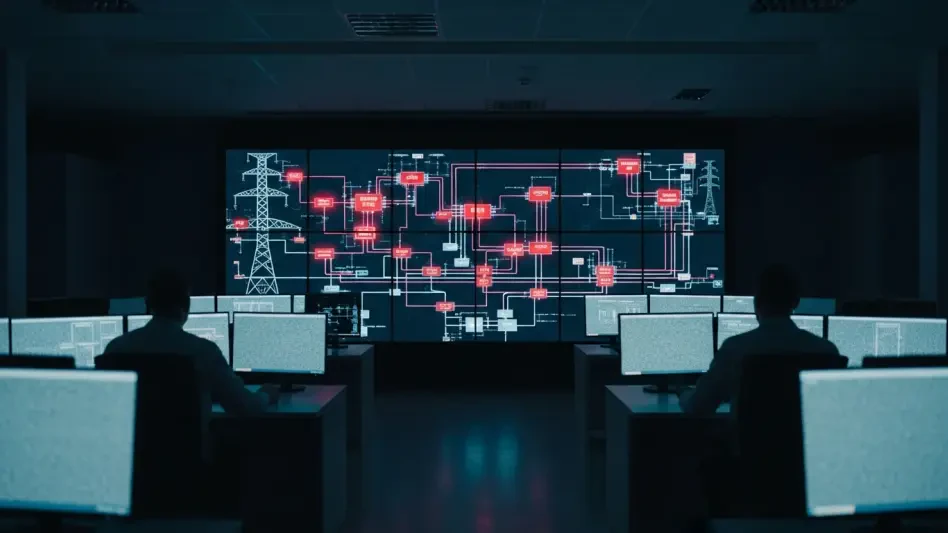

The path to achieving robust supply chain trust is fraught with obstacles, particularly in the U.S. manufacturing sector. Fragmented practices across organizations often result in significant visibility gaps, making it difficult to track components through complex networks. This lack of clarity increases the likelihood of errors, delays, and undetected issues that can compromise product quality.

Among the most pressing risks are counterfeit products infiltrating supply chains, alongside compliance failures that can lead to legal and financial repercussions. Cybersecurity threats further exacerbate these concerns, as malicious actors target vulnerabilities in digital tracking systems. Such challenges not only undermine trust but also pose threats to national security and economic stability.

The Meta-Framework offers potential solutions through secure data exchange mechanisms and controlled disclosure principles. By enabling stakeholders to share only necessary information, it mitigates privacy concerns while ensuring accountability. These features provide a foundation to tackle fragmentation and enhance visibility, paving the way for more reliable supply chain operations.

Regulatory and Compliance Landscape

Navigating the regulatory environment is a critical aspect of supply chain traceability in U.S. manufacturing. A myriad of legal, contractual, and industry standards shape compliance requirements, demanding rigorous documentation and transparency. Failure to meet these obligations can result in severe penalties and damage to reputational standing.

The Meta-Framework supports adherence to these mandates by providing a structured system for recording and validating supply chain events. It ensures that data shared among stakeholders meets external requirements while safeguarding confidential information through controlled access. This balance is essential for maintaining trust without exposing proprietary details.

NIST’s contributions extend beyond technical solutions to include setting standards that foster governance and risk management. By aligning with industry best practices, the framework helps organizations demonstrate compliance effectively. This alignment not only aids in meeting current regulations but also prepares stakeholders for evolving mandates in a dynamic policy landscape.

Future Outlook for Supply Chain Trust

Looking ahead, the Meta-Framework holds significant promise for transforming supply chain integrity and transparency in manufacturing. Its structured approach to traceability could redefine how stakeholders verify product authenticity and manage risks over the coming years. As adoption grows, the potential for widespread impact on operational efficiency becomes increasingly evident.

Emerging technologies such as blockchain and advanced analytics may further complement the framework, enhancing its capabilities for secure data handling. These innovations could provide additional layers of protection against tampering and improve real-time tracking across ecosystems. Integrating such tools will be crucial for staying ahead of sophisticated threats.

Global economic conditions and regulatory shifts will also influence the framework’s implementation trajectory. Adapting to these changes will require continuous refinement of interoperability and privacy mechanisms. Ongoing research into these areas, alongside stakeholder engagement, will ensure that the framework remains relevant and effective in addressing future challenges.

Reflections and Next Steps

Reflecting on the insights gained, it becomes clear that NIST’s Meta-Framework marks a turning point in addressing longstanding supply chain vulnerabilities. Its emphasis on secure, interoperable traceability systems tackles critical issues of trust and accountability head-on. The collaborative efforts behind its development highlight a shared dedication to safeguarding manufacturing integrity.

Moving forward, stakeholders need to prioritize active engagement in refining and adopting the framework’s principles. Establishing robust governance structures is essential to support implementation across diverse industries. Investing in training and technology integration will further ensure that organizations can leverage the framework’s full potential.

As supply chains continue to evolve, exploring partnerships for innovation stands out as a key strategy. Encouraging dialogue among manufacturers, regulators, and technology providers could drive the development of complementary tools and practices. This proactive approach promises to sustain trust and resilience, securing the future of U.S. manufacturing on a global stage.