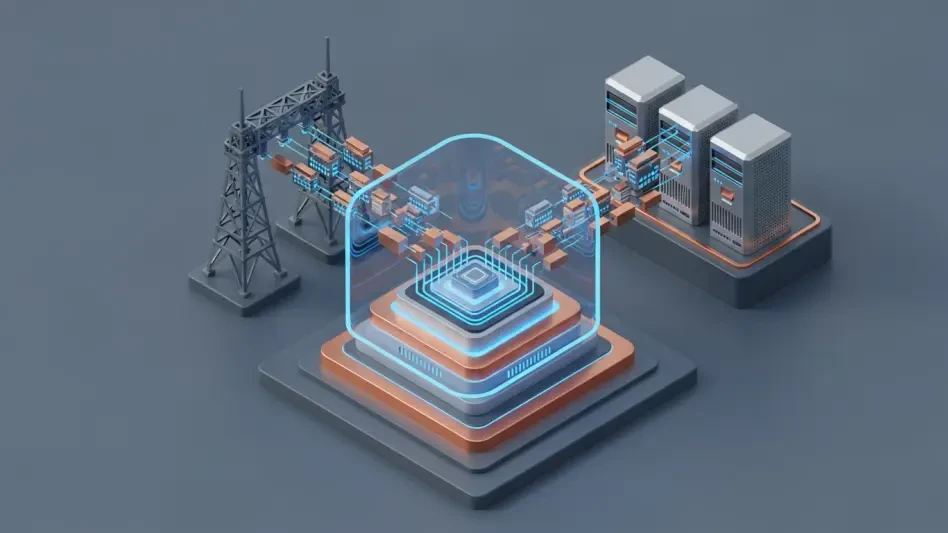

In a world where technology dictates the pace of progress, a staggering 90% of modern devices—ranging from smartphones to military equipment—rely on semiconductors, the tiny chips that power innovation, yet beneath this dependency lies a vulnerability. A single cyberattack on a semiconductor supply chain can halt production, costing billions and threatening national security, and Japan, a global leader in this critical industry, faces mounting pressure as nation-state hackers target these supply chains with increasing sophistication. How can newly implemented guidelines for operational technology (OT) security become the shield that protects this vital sector from digital warfare?

The significance of this issue cannot be overstated. Semiconductors are not just components; they are the backbone of economic stability and global connectivity, with Japan playing a pivotal role as a supplier to international markets. Disruptions in this arena, as seen in recent chip shortages, have caused delays in everything from automotive production to consumer electronics. This story delves into how Japan’s OT Security Guidelines, crafted by the Ministry of Economy, Trade and Industry (METI), aim to fortify semiconductor supply chains against cyber threats, ensuring that the gears of technology keep turning uninterrupted.

Why Semiconductor Supply Chains Are a Cybersecurity Battlefield

Semiconductor supply chains have emerged as prime targets in the shadowy realm of cyber warfare due to their strategic importance. Nation-state actors recognize that disrupting these networks can cripple economies and destabilize governments, making them high-value objectives for espionage and sabotage. A breach in a single factory can cascade through global markets, as chips are integral to countless industries, from healthcare to defense.

The complexity of these supply chains exacerbates their vulnerability. Spanning multiple countries and involving numerous stakeholders—from raw material suppliers to chip designers—each link presents a potential entry point for attackers. Japan, with its advanced manufacturing hubs, stands at the forefront of this battle, facing threats that exploit both digital and physical weaknesses in the production process.

Recent data paints a stark picture: cyberattacks on industrial sectors, including semiconductors, have surged by over 50% in the past two years, according to industry reports. This alarming trend underscores the urgent need for robust defenses, prompting Japan to roll out OT guidelines specifically tailored to counter such risks. These measures aim to transform the industry’s approach to security, addressing the unique challenges of protecting operational environments.

The Vital Importance of Semiconductors for Global Stability

Beyond their role in everyday gadgets, semiconductors are linchpins of national security and economic health. Military systems, critical infrastructure, and even financial networks depend on these chips, meaning any disruption can have far-reaching consequences. Japan’s position as a key producer amplifies the stakes, as its output supports allies and partners worldwide.

Historical shortages, such as those experienced during global crises, have exposed the fragility of this ecosystem. When production faltered, automakers slashed output, hospitals delayed equipment upgrades, and consumers faced empty shelves for tech products. These ripple effects highlight why safeguarding Japan’s semiconductor industry is not just a local concern but a matter of international stability.

Protecting this sector requires more than traditional IT security; it demands a focus on operational technology, where production lines and machinery intersect with digital systems. The latest guidelines from METI address this intersection, aiming to prevent cyber incidents from derailing the intricate balance of global supply and demand. This proactive stance is essential to avert crises before they escalate.

Core Elements of Japan’s OT Security Guidelines for Chip Protection

Japan’s OT Security Guidelines, developed by METI, provide a comprehensive framework to shield semiconductor factories and their supply chains. A cornerstone of this approach is holistic defense, ensuring that every segment—from raw material procurement to final chip assembly—is secured. Weak points, such as third-party suppliers with lax protocols, are identified as critical areas for improvement, with actionable steps to close gaps.

Another focus is on protection priorities, aligning with global standards like the NIST Cybersecurity Framework 2.0. The guidelines emphasize safeguarding production continuity, confidential data, and product quality, while also addressing environmental and human safety. This multi-faceted strategy ensures that security measures do not compromise operational integrity or ethical responsibilities in high-stakes manufacturing environments.

The guidelines also tackle advanced threats, particularly from nation-state Advanced Persistent Threats (APTs), by advocating for robust threat intelligence. Additionally, they acknowledge operational hurdles in OT settings, where legacy systems and non-stop production—often involving over 2,000 pieces of equipment per factory—limit traditional fixes like patching. Alternative strategies, such as network isolation, are proposed to mitigate risks without halting critical workflows.

Expert Perspectives on Strengthening Semiconductor Security

Insights from industry leaders and government bodies lend weight to the guidelines’ approach. Representatives from the National Institute of Information and Communications Technology (NICT) have emphasized the need for real-time threat monitoring, stating that “semiconductor facilities must anticipate attacks before they occur, leveraging shared intelligence to stay ahead of adversaries.” This perspective aligns with recommendations from JPCERT/CC, which stress collaboration across sectors to combat evolving risks.

Alignment with international frameworks, such as NIST CSF 2.0 and SEMI E187, further validates Japan’s strategy. Data from IT-ISAC’s Semiconductor Industry SIG reveals that over 60% of reported incidents in this sector stem from supply chain vulnerabilities, reinforcing the guidelines’ focus on end-to-end protection. Hypothetical scenarios, like a breach at a materials supplier leading to contaminated chips, illustrate the potential fallout of neglecting even minor links in the chain.

These expert voices and evidence highlight a unified push for proactive measures. Government and industry collaboration, as seen in platforms like IT-ISAC, provides a foundation for actionable intelligence, ensuring that the guidelines are not just theoretical but grounded in the realities of cyber threats facing semiconductor production today.

Practical Steps to Bolster Semiconductor Supply Chains

Implementing Japan’s OT Guidelines requires concrete actions tailored to the semiconductor industry’s unique needs. A starting point is creating a detailed asset inventory, prioritizing equipment and systems based on their impact on business operations. Tools like the Common Vulnerabilities and Exposures (CVE) database and National Vulnerability Database (NVD) can assist in identifying and addressing weak spots efficiently.

Network segmentation through IT/OT demilitarized zones (DMZs) offers another layer of defense, especially for factories relying on external services to enhance yield. These secure buffers isolate critical systems from internet-based threats, reducing the attack surface. Simultaneously, physical security in fabrication areas must be tightened, using biometric access controls to prevent unauthorized entry into sensitive clean rooms.

For environments where immediate updates are impractical, alternative tactics like microsegmentation and defense-in-depth strategies are recommended. Such measures ensure that even if one system is compromised, the damage remains contained. By adopting these steps, stakeholders can balance robust security with the relentless demands of production, creating a resilient framework for the future.

Reflecting on the journey to secure Japan’s semiconductor supply chains, the strides made through METI’s OT Guidelines mark a turning point in addressing cyber vulnerabilities. The collaborative efforts between government, industry experts, and international standards bodies lay a solid foundation for resilience against sophisticated threats. Looking ahead, the focus shifts toward continuous adaptation—updating defenses to match emerging risks and integrating cutting-edge technologies. Stakeholders are encouraged to prioritize ongoing threat intelligence and cross-border partnerships, ensuring that the industry remains a step ahead of adversaries. This commitment to vigilance and innovation promises to safeguard not just a critical sector, but the global stability it underpins.