The manufacturing sector is undergoing a profound shift, fueled by digitization and automation, presenting both opportunities and challenges. This transformation, characterized by integrated technologies and automated processes, leads to heightened exposure to cybersecurity threats. As manufacturers increasingly rely on digital ecosystems, the need to safeguard operational technology (OT) and industrial control systems (ICS) against sophisticated cyberattacks becomes paramount. Issues such as supply chain vulnerabilities and talent shortages further compound these risks, highlighting the urgent necessity for robust cybersecurity measures. This complex landscape demands strategic approaches balancing security with uninterrupted production—critical in a sector where downtime can produce significant financial repercussions.

Escalating Cyber Threats in Manufacturing

The cybersecurity threat landscape facing modern manufacturing is becoming progressively perilous, with ransomware attacks, OT vulnerabilities, and state-sponsored hacking constituting some of the most severe challenges. These threats significantly impact industrial control systems (ICS) and critical manufacturing infrastructure, often bringing production to an abrupt halt, which can lead to substantial financial losses. An alarming report from Dragos, an industrial cybersecurity firm, reveals a marked increase in ransomware incidents, drawing attention to the vulnerabilities prevalent within the sector. The intricacies of these threats are such that state-sponsored actors, often motivated by geopolitical tactics, exploit weaknesses in the OT environment.

Building awareness around these threats is not just a preventative measure; it is a necessity in the current climate, where cybercriminals and malicious entities focus on invaluable industrial data. These attacks are sophisticated, targeting the weakest spots within the supply chain to maximize disruption. Manufacturing entities must understand and anticipate the evolving nature of cyber threats if they are to mitigate risks effectively. This requires ongoing assessments, vigilance, and the deployment of technology to ensure that potential entry points for attackers are secured. Understanding threat dynamics is key to developing appropriate responses and securing manufacturing operations against future vulnerabilities.

Balancing Security and Operational Continuity

Maintaining continuous operations while safeguarding digital infrastructure presents a unique challenge to manufacturers. Unlike conventional IT environments, where intermittent downtime for security updates is often feasible, manufacturing settings demand unbroken production cycles. This makes typical cybersecurity protocols, such as patching or detailed incident responses, less effective or even impossible during operational hours, given the risk of disrupting manufacturing output. The priority is to incorporate cybersecurity strategies that align seamlessly with operational continuity to ensure that security measures do not impede productivity. Effective cybersecurity in manufacturing environments necessitates methodologies that integrate with existing processes without compromising system availability.

This intricate balance between security and operational uptime requires a paradigm shift in cybersecurity practices within the sector. Manufacturers are urged to incorporate protective measures that are responsive and adaptive, catering specifically to the sector’s unique needs. Cybersecurity frameworks suited to manufacturing operations must prioritize real-time analysis and the ability to identify threats swiftly. This includes implementing technologies designed to operate discreetly within manufacturing processes, anticipating and responding to threats without causing disruptions. For manufacturers, integrating such cybersecurity strategies is no longer optional—it is an operational imperative, necessary to safeguard both the workforce and the technology they depend on.

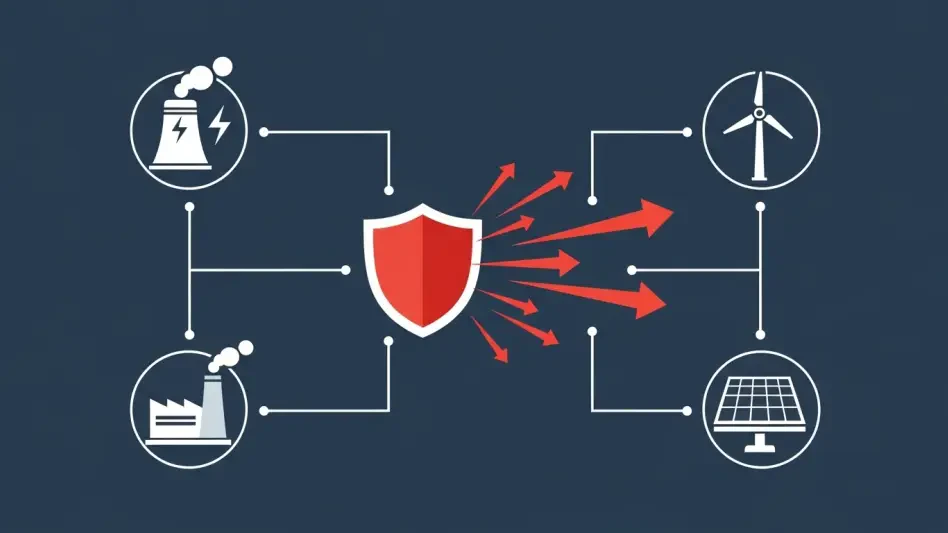

Vulnerabilities in the Digital Supply Chain

The increasingly interconnected nature of supply chains exacerbates cybersecurity vulnerabilities in manufacturing. Each new supplier integrated into the digital supply chain contributes potentially exploitable entry points that cybercriminals may target, emphasizing the necessity for rigorous security protocols. As manufacturers depend more on digital interdependencies, securing the breadth of the supply chain becomes increasingly critical. This security extends beyond traditional borders, from the initial supplier vetting process to ongoing assessments and audits. Implementing such measures ensures that vulnerabilities within any part of the supply chain do not translate into significant risks to the overall operation.

Manufacturers are compelled to adopt standardized protocols to mitigate these vulnerabilities, promoting secure data exchange and vendor qualifications to assure trustworthiness. Industry standards like IEC 62443 assist in structuring secure environments, offering frameworks for lifecycle oversight and vendor compliance. These protocols are crucial, as they provide comprehensive guidelines to effectively manage and mitigate third-party risks. The need for these standardized approaches becomes more pressing as manufacturers rely on just-in-time deliveries. Ensuring security across supply chains is a prerequisite for creating a resilient manufacturing ecosystem capable of enduring persistent cyber threats that target operational weaknesses.

Addressing the Cybersecurity Talent Gap

The cybersecurity talent gap poses a significant challenge to the manufacturing sector, especially given the complexity and scope of modern digital threats. Traditional approaches to cybersecurity training are inadequate for meeting the needs of this rapidly evolving field. Manufacturers must adopt innovative training programs that focus on upskilling both OT and IT personnel, fostering a culture of cybersecurity awareness at all organizational levels. The development of tailored training programs is vital in equipping workers with the knowledge to manage and respond to cyber threats effectively, reducing dependence on limited external resources.

Investing in workforce development ensures that factory-floor staff are proficient in handling cybersecurity issues and employing proactive measures. Advanced cybersecurity technologies, such as zero trust architecture and AI-based threat detection, offer transformative capabilities, enhancing training paradigms by providing practical tools for threat identification and management. These technologies facilitate real-time access control and anomaly detection, empowering staff to act promptly and decisively against potential threats. For the manufacturing industry to thrive amid escalating cyber threats, fostering a skilled, security-conscious workforce is essential. Empowered and informed personnel represent a critical line of defense in sustaining operational resilience.

Technological Innovations in Cybersecurity

Advancements in cybersecurity technology prove crucial as manufacturers combat evolving threats. The adoption of zero trust architecture and AI-driven threat detection systems represents a proactive approach in safeguarding OT environments. Zero trust models operate on the principle that no user or system should be trusted inherently, necessitating robust verification processes before granting access. This security paradigm significantly reduces the risk of unauthorized exposure and limits the scope for malicious activity. Alongside these models, AI-based systems revolutionize threat detection by enabling rapid identification of anomalies and potential security breaches, providing real-time insights that bolster defenses.

Manufacturers who implement these technological innovations find themselves better equipped to handle unprecedented threats targeting complex OT systems. Comprehensive access controls derived from zero trust architecture and AI integrations offer a new tier of security, managing access dynamically and detecting potential intrusions promptly. These advancements not only enhance security but also improve overall operational efficiency by minimizing downtime associated with threat responses. The utilization of these technologies signals a shift in how manufacturers approach cybersecurity, underscoring the need for integrated, intelligent solutions capable of addressing the multifaceted challenges prevalent in today’s manufacturing environment.

Collaborative Efforts and Industry Events

Collaboration within the cybersecurity domain is essential for reinforcing resilience in the manufacturing sector. Events like ‘Industrial Cyber Days Manufacturing’ offer unique platforms for industry stakeholders to exchange knowledge, insights, and strategies aimed at strengthening cybersecurity measures across manufacturing operations. These gatherings promote a unified approach to tackling industry-specific challenges, fostering an environment conducive to shared learning and innovation. Discussions cover a spectrum of issues, including threat intelligence, best practices in digital safeguarding, and the development of frameworks that align cybersecurity with operational objectives.

Such collaborative endeavors prove invaluable in nurturing a culture of cybersecurity awareness and preparedness among manufacturers. They empower participants by facilitating access to expert-led discussions and actionable strategies curated specifically for defending digital manufacturing ecosystems. This exchange of expertise drives collective progress, helping manufacturers adapt to emerging threats and leverage cutting-edge technologies. As the manufacturing landscape becomes more interconnected, fostering collaborative networks is increasingly critical. Collective efforts from industry events serve as catalysts for instilling cybersecurity consciousness, enhancing the sector’s resilience, and ensuring sustainable growth amid escalating cyber threat levels.

Analyzing Expert Insights on Cyber Threats

Industry experts offer invaluable perspectives on the complexity of cyber threats confronting manufacturers today. These specialists emphasize the sophisticated tactics utilized by attackers, driven by geopolitical tensions and financial motives. The acceleration of state-sponsored activities, notably by Chinese APTs, poses serious concerns, as these actors often bypass conventional security measures to compromise manufacturing operations. Insights from cybersecurity professionals stress the importance of understanding these adversary motivations and strategies to develop effective countermeasures.

Experts highlight the trend of attackers exploiting soft infrastructure vulnerabilities—often areas with insufficient security due to negligence or outdated practices. Addressing these weaknesses requires a thorough reevaluation of existing security protocols, with an emphasis on adopting advanced protection strategies like zero trust models and AI-enhanced threat detection technologies. Professionals advocate for continuous monitoring and real-time threat intelligence to preemptively identify and mitigate potential breaches. These measures are vital for sustaining operational integrity and resilience against increasingly complex cyber threats targeting the manufacturing industry.

Integrating Cybersecurity into Organizational Culture

Integrating cybersecurity within the core of an organization is imperative for manufacturing entities to withstand cyber threats effectively. Establishing a cybersecurity-centric culture involves embedding protective practices deeply into operational frameworks, ensuring that security permeates all business units and production processes. Central to this transformative approach is the adoption of zero trust models, which fortify the organization’s defenses by fundamentally altering how access is granted and managed across the digital landscape.

AI-enhanced threat detection capabilities supplement these efforts, providing cutting-edge tools for recognizing and responding to potential threats. Manufacturers are urged to implement structured third-party assurance programs to verify vendor security practices, reducing external risks to operations. Comprehensive training programs enhance staff readiness, bridging the gap between IT and OT cybersecurity needs while promoting cross-functional collaboration. By unifying efforts across departments, manufacturers can create cohesive strategies that protect operations without compromising uptime goals or productivity.

Structuring Proactive Supply Chain Security

The imperative for proactive supply chain security mounts as manufacturers increasingly rely on digital interdependence. Securing the entire supply chain from end to end is crucial in preserving operational integrity and mitigating third-party risks. It requires meticulous oversight and robust security frameworks, such as IEC 62443, to structure and enforce vendor trust zones efficiently. These frameworks provide comprehensive guidelines for lifecycle oversight, ensuring that security measures remain intact and effective over time.

Adopting standardized contractual security requirements further supports the development of secure supply chains, facilitating seamless and secure interactions between vendors and manufacturers. These measures are essential in countering the rising cyber threats that exploit weak links within the supply chain, potentially triggering widespread disruptions. Proactive approaches to supply chain security safeguard manufacturing operations from the vulnerabilities presented by digital interdependencies. In doing so, they enhance the sector’s resilience, fostering an environment where cybersecurity and operational continuity coexist harmoniously.

Enhancing Manufacturing Resilience

Managing continuous operations while securing digital infrastructure is a unique challenge for manufacturers. Unlike traditional IT settings, where occasional downtime for security updates is possible, manufacturing demands uninterrupted production cycles. This requirement makes standard cybersecurity practices like patching or detailed incident responses either less effective or outright impossible during working hours due to the risk of halting production. Therefore, the focus should be on adopting cybersecurity strategies that seamlessly integrate with operational continuity, ensuring security isn’t a hindrance to productivity. Effective cybersecurity in these environments requires methods that align with current processes without threatening system uptime.

This delicate balance between security and operational uptime calls for a significant shift in cybersecurity approaches within the sector. Manufacturers must adopt protective measures that are responsive and adaptive, addressing the specific needs of the industry. Cybersecurity frameworks in manufacturing should emphasize real-time analysis and the swift identification of threats. Implementing technologies that work quietly within manufacturing processes is crucial, allowing for anticipation and immediate response to threats without disruption. For manufacturers, integrating these strategies isn’t just optional—it’s an operational necessity, crucial for safeguarding both their workforce and the technology essential to their operations.